The New Generation of BTAS-16 software and hardware is here!

Introducing the All New BTAS-16K Software and Hardware! With a wide array of updates and improvements, consider upgrading today!

BTAS-16

Computerized Battery Test and Analysis System

Overview

General Specifications

Part Numbers

Documents

New BTAS-16K Software!

New BTAS-16K Hardware!

New Crowns for SAFT Batteries

New Accessories for Testing Lead-Acid Batteries

Overview

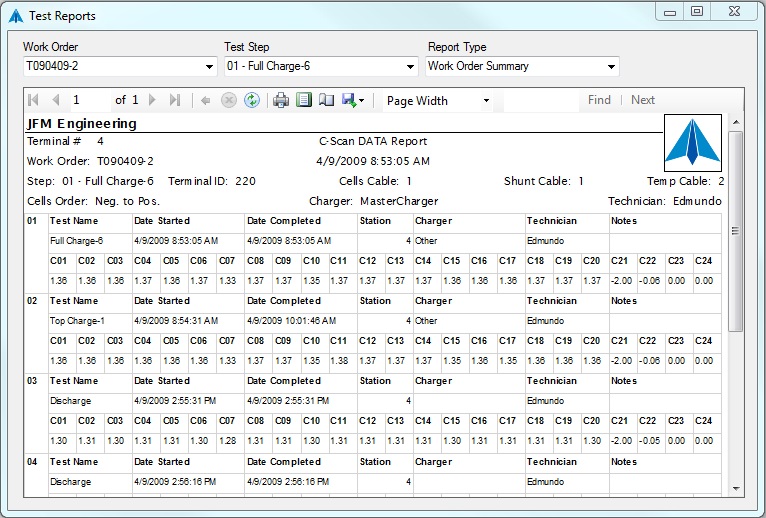

The task of testing an aircraft’s Nickel-Cadmium batteries is complicated and involved because of the high number of cell voltage readings that need to be taken during testing. Taking voltage readings from all 20 cells in the typical nickle-cadmium aviation battery multiple times is laborious and error prone, but must be done to properly estimate the condition of the battery under test.

In order to simplify this process, JFM Engineering offers the BTAS-16 system. The BTAS-16 system provides complete automation of the battery testing process; taking battery and cell readings while assuming control of the Charger-Analyzer used during testing. The BTAS-16 system will greatly improve the accuracy and efficiency of your battery shop.

How complete is your battery testing process?

Do you take periodic cell readings?

Can you easily compare new test results with prior ones?

What kind of an audit trail do you have?

The BTAS-16 addresses all of these questions!

With the BTAS-16 you can:

Automatically Take Readings of

Battery Current

Battery Voltages

Individual Cell Voltages

Battery Temperatures

Water Dispensed into Each of the Cells (via the MasterFiller)

Automatically Short Cells at the End of Discharge

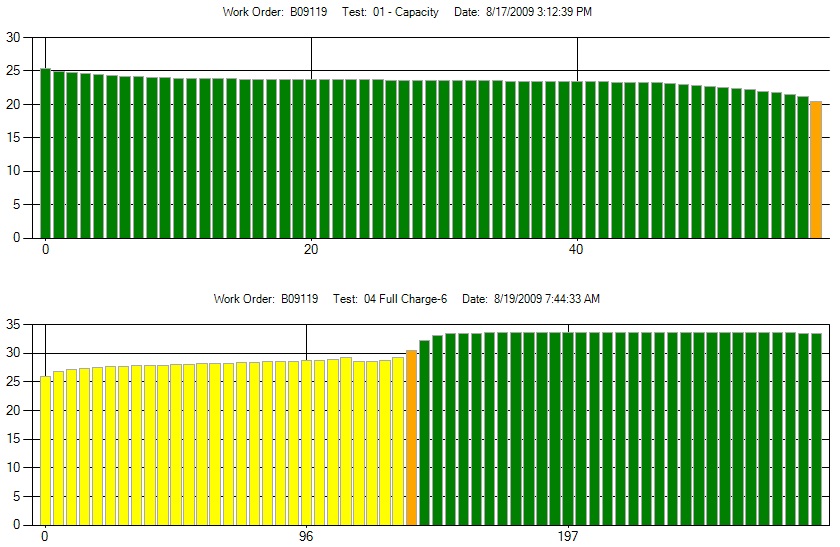

View the Data as it is Being Recorded

Tabular numerical readings

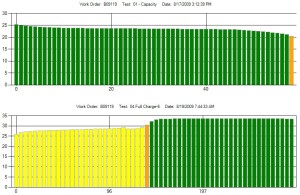

Color coded Bar-Graph display

As it is Being Recorded

At the End of the Test (Summary Reports)

Archive and Compare Test Results

Generate PDF, Word or Excel Reports

Print Reports

All Data Automatically Archived to BTAS-16 Database

Keep Track of

Work Orders and Batteries by Serial Number, Work Order, Customer or Test Date

From One Terminal to 16 Terminal per Station

Possibility of Linking Multiple Stations via a Server

Can Grow as Your Battery Shop Expands

Universal Cell Cables With Clips

Custom Contact Arrangements (Crowns) for Rapid and Reliable Connections

Designed Specifically For Aircraft Battery Repair Stations

The BTAS-16 is Not and Adaption of a Complicated Laboratory System

It is Designed Specifically to Fit the Needs of Battery Shops of All Sizes and was Developed and Used in JFM’s Own Battery Shop.

General Specifications:

- Max number of Terminals: 16

- Max number of batteries per Terminal: One battery up to 24 cells, two batteries with 11 cells or three batteries with 7 cells.

- Max number of Terminals per Charger-Analyzer: Two if the Charger-Analyzer is a Superseder type, and one if other type.

- Measurement of Charge-Discharge current: Through an internal shunt in the MasterCharger, MiniMasterCharger, Superseder IIIC/240400TC, SupersederXG/24-400xg, or through an external shunt in the Charger-Analyzer battery cable.

- Monitoring of battery temperature: Through the Temp-Plate accessory

- Monitoring and Control of the MasterCharger, MiniMasterCharger, Superseder and 24-400 Charger-Analyzers (1): On-Off detection and Start-Stop synchronization with the recording of battery data.

- Computer: Standard Dual Core PC running Windows 7 or better

- Printer: Standard Laser (B/W) or Inkjet (color)

(1) Requires the “C modification for the Superseder III and 24-400TCharger-Analyzers. (Note that the SupersederXG and 24-400xg are designed to communicate with the BTAS16). Other brands and types of Charger-Analyzers could be interfaced (consult with the factory ).

Part Numbers

- 9896204102 – BTAS-16K Basic Package for two batteries. Includes software, data interface, two C-Scans, Cell simulator, two 20 Cells Cables and all other required cabling.

- 9896204101 – BTAS-16K Basic Package for one battery. Includes software, data interface, one C-Scan, Cell simulator, one 20 Cells Cable and all other required cabling.

- 9896204011 – BTAS-16K Expansion Kit. Includes one C-Scan and one 20 Cells Cable.

- 9895202804 – Four Battery Cable: For monitoring of emergency packs.

- 9895202805 – Two Battery Cable: For mainship batteries with inaccessible cells.

Documents

BTAS-16K Installation Guidelines-V2.0

New BTAS-16K Software!

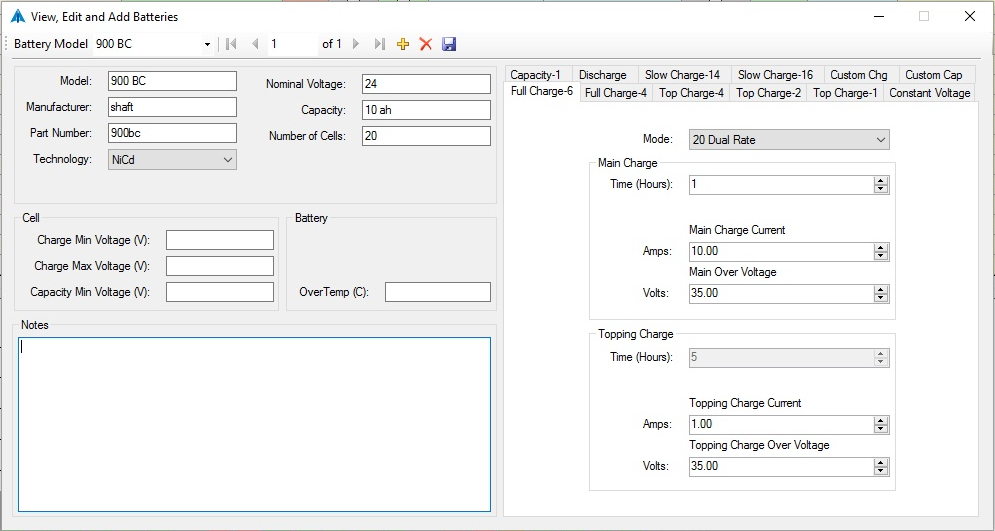

The original BTAS-16 software has been completely rewritten, from the ground up, as the all new BTAS-16K software. The BTAS-16K software is designed to take advantage of all that the modern Windows environment has to offer. While the BTAS-16K software retains all of the same functionality as the original BTAS-16 software, it also offers several improvements:

- Complete Integration With JFM’s Intelligent Charger-Analyzers

- Combination tests, which transfer between Charge and Discharge modes automatically.

- Cell level analysis, which will stop a test in the event that a cell exhibits a negative delta voltage during charge.

- The Ability to Pre-Program Intelligent Charger-Analyzers Based on Battery Model Profiles Saved in the BTAS-16K Data Base

- Faster Operation and A More Responsive Graphical User Interface

- Improved Plotting Graphics and Battery Reports

- Status Updates by Email or Text Message

- Automatic Updating Through the Internet

- Built-In Ability to Export Reports to PDF, Excel or Word

Along with these Improvements, we will also be rolling out further upgrades to the BTAS-16K software through it’s Automatic Updating feature down the line.

Enhanced Reporting

Improved Graphics

Updated and Easy to Use Database Interface

New BTAS-16K Hardware!

The next generation of BTAS-16 hardware is here! With smaller footprints and metal enclosures the BTAS-16 hardware is better than ever! The new generation of BTAS hardware is also capable of higher sampling rates, allowing for higher resolution analysis of batteries under test.

JFM is also now proud to offer a new product the BTAS-16 Shorting Box. The shorting box allows for the automated cell shorting of a battery through a standard BTAS connection ( Clips Cable or Crown ).

C-Scan and Shorting Box Combination

Contact JFM to upgrade your BTAS system today!

C-Scan

Shorting Box

Data Interface

Cell Simulator

Clip Cable

New Crowns for SAFT Batteries

P/N 9895203C01 – Universal Crown for SAFT 20 Cell Batteries

P/N 9895203C02 – Crown for SAFT 5317, 21 Cell Battery

P/N 9895203C03 – Crown for SAFT 4579, 20 Cell Batteries

New Accessories for Testing Lead-Acid Batteries

New Software and Accesories are now available to allow the analysis of Lead-Acid Batteries under test using the BTAS-16

New Software and Accesories are now available to allow the analysis of Lead-Acid Batteries under test using the BTAS-16

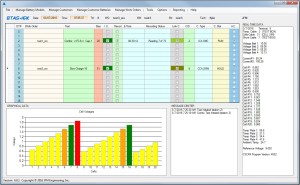

Although the BTAS-16 was initially designed to facilitate the testing of Nickel-Cadmium Batteries, the BTAS-16 now has been updated to appropriately color code bar graphs specific to Lead-Acid Batteries test results. A new Interface Box with connections to the BTAS-16 plugs into the Battery Cable and facilitates the reading of the voltage of the batteries by the BAS16 software. Once the BTAS-16 recognizes the presence of this interface, it makes available a dialog to identify the battery as Lead-Acid and to show the nominal battery voltage (12V, 24V, etc).

During charge, the bar-graphs and reports will show how the battery voltage rises until it reaches the float voltage point at which time the current will diminish as the battery charges up. With this system, it is possible to identify when a battery has reached the end of charge or if the battery requires a high level of current to maintain the programmed voltage (at the Charger).

During Discharge (Capacity Test), bar-graphs and reports will display the voltage profile that can be used to determine if the battery meets the required discharge performance or it it falls short of the established discharge time.

An additional Accessory, called the Four Battery Cable, is available for testing of small batteries and battery packs of any chemistry, where cells are not accessible. Once the BTAS-16 recognizes the presence of this interface, it makes a available a dialog to identify the battery type as Nickecl-Cadmium, Lead-Acid (or other) and record the number of cells, if Nickel-Cadmium, or the nominal battery voltage if Lead-Acid.

Contact JFM Engineering for more details, pricing and availability.

![OneCrown[1]](https://www.jfmeng.com/wordpress_test/wp-content/uploads/2015/06/OneCrown1-300x240.jpg)